“Self-regulating heating cables, a technological innovation in the field of Electrical Tracing, offer a dynamic and effective solution for maintaining optimal temperature in a variety of industrial applications.

In this article, Let's deepen our understanding of these cables, examining its components and functioning, as well as its application in the context of the Electrical Tracing System.

“

Components of Self-Regulating Heating Cables

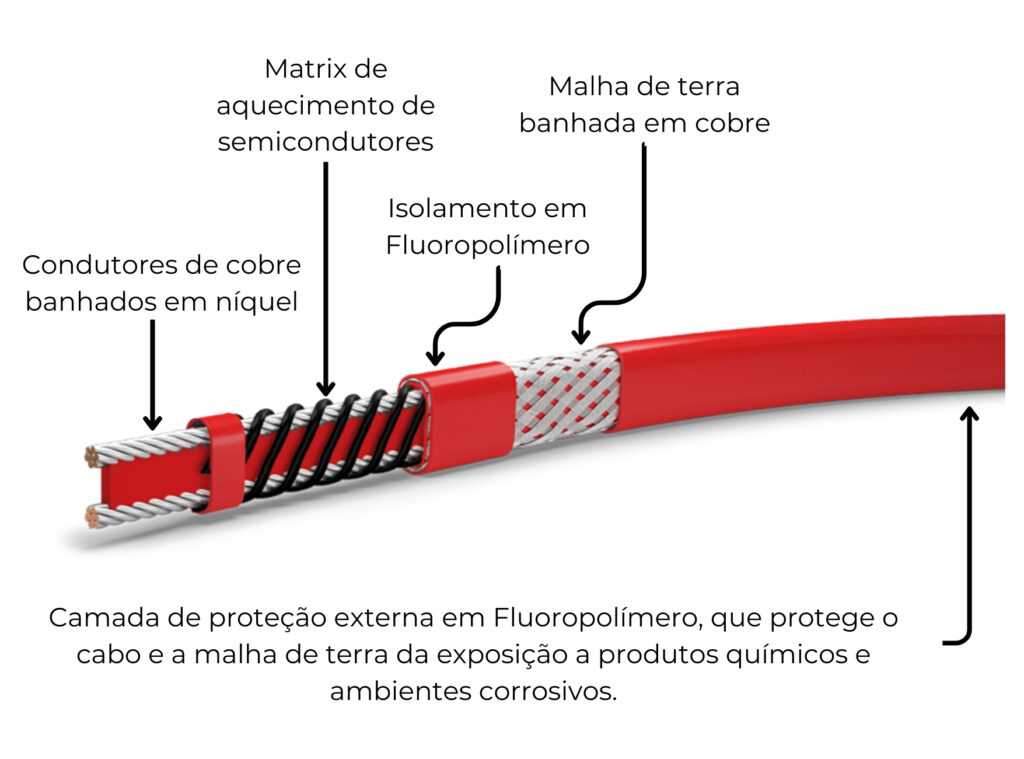

Self-regulating heating cables have a basic configuration, as shown below, and are made up of some essential components:

- Nickel Plated Copper Conductors: These conductors form the base of the cable and are responsible for carrying electrical current along the length of the cable..

- Self-regulating Polymeric Conductive Core: The conductive core is the heart of self-regulating cables, composed of polymeric material that has self-regulating properties. This unique feature allows the cable to adjust its own heating output in response to ambient temperature variations..

- Inner and Outer Cover: Inner jacket provides additional protection to the cable's internal components, while the outer cover provides mechanical resistance and protection against environmental damage.

- Tinned Copper Mesh (for Grounding): The presence of a tinned copper mesh around the cable allows for an effective earth connection, ensuring additional safety during operation.

Operation of Self-Regulating Heating Cables

Self-regulating heating cables operate on a thermal self-regulating principle. When the ambient temperature decreases, the electrical resistance of the internal polymeric material decreases, allowing more current to flow through the cable and, consequently, generating more heat. On the other hand, when it increases at room temperature, the electrical resistance of the polymeric material increases, reducing the electrical current and, consequently, the heat generated.

This self-regulating mechanism ensures uniform heat distribution along the trace line, keeping it at the ideal temperature to prevent freezing or ensure continuous flow of temperature-sensitive processes.

Application in Electrical Trace

Self-regulating heating cables are widely used in Electrical Pipe Tracing system, tanks and industrial equipment.

They offer an adaptable and efficient solution for maintaining optimal temperature in a variety of industrial environments, from controlled indoor environments to outdoor locations subject to extreme weather variations.

Their ability to self-regulate makes them especially suitable for applications where the ambient temperature can vary significantly over time..

Therefore, The Electrical Tracing System is an important solution in maintaining operational efficiency and preventing temperature-related problems.

Scooter: projection and installation of the Electric Trace

Tayga offers comprehensive design and installation services for Electrical Tracing systems, including proper selection and sizing of self-regulating cables to meet the specific needs of each application. Combining technical expertise with high quality products, Tayga guarantees reliable and efficient solutions in a variety of industrial sectors.

If your company is looking for a complete and reliable solution for your electrical tracing needs, Tayga is ready to help. With a team of highly qualified experts and a wide range of high quality products, We are prepared to design and install bespoke electrical tracing systems to meet your specific needs. Contact us today to learn more about how we can help optimize your industrial processes with our state-of-the-art electric heating solutions.

Na tayga, We offer customized heating solutions that can be tailored to meet the operational and budgetary requirements of any industry. Our experts are available to guide you in selecting the best heating option for your facility..

Contact us today to learn more about our state-of-the-art heating solutions. We are available through do site (click here) or by e-mail contato@taygahs.com or at phone and Whatsapp (21) 9.8819-3687.

We also recommend reading our materials on the heating and insulation systems implemented by Tayga (just click and you will be redirected):