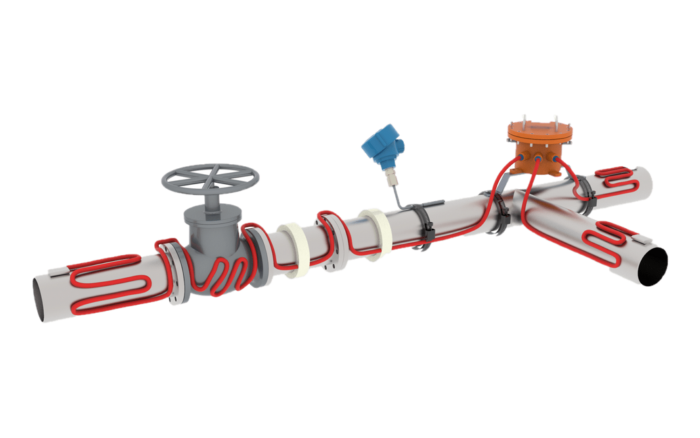

“The electrical trace system ensures that equipment and pipes remain at optimal temperatures constantly. However, like any technology, problems may arise that affect productivity. Therefore, Knowing how to conduct troubleshooting is crucial to maintaining a functional electrical trace system.”

It is important to approach fault finding in an electrical trace cable with caution., as there are several steps involved in carrying out proper field maintenance.

We recommend dividing the task into three sections, in the following order: the power cord, the electrical trace cable and thermostats, to ensure successful identification of defects, thus enabling continuous operation of your electrical trace system.

Power Cord

For security reasons, you should always disconnect the power cord at the panel and insulate the wires first. Open the field power junction box and disconnect any electrical trace cables from the terminals.

Then, you can proceed with the megger test for the power cable located between the junction box and the panel.

If you find a low IR value (below 10M ohms), check and make sure there is no intermediate connection box installed. If there is, disconnect power cords and check each section. Do not neglect carrying out a “tested the barrel” on each power cord. Repair or replace the power cord, if necessary, if there is any defect.

Electrical Trace Cable

Perform a megger test for the(s) cape(s) electrical trace from the power junction box. In case of a low IR value (below 10M ohms), you can detect where the defect is through the following steps.

Stage 1: Check the Electrical Trace Cable

In the first place, Make sure the electrical trace cable is only made up of one section. However, if connection boxes are installed, disconnect the electrical trace cables from the connection box and perform the megger test on the individual sections. Then, inspect the electrical trace cable from end to end to verify that it is not damaged.

As most of the electrical trace cable is covered by thermal insulation, the probability of detecting damage will be low. Therefore, try to remember when and where the electrical trace cable was worked on and if there were any instances of damage to the electrical trace cable at that time. Another option is to use a portable cable fault locator to send an electrical pulse to the electrical trace cable..

Stage 2: Check the Junction Box

Sometimes, the defect may be in the junction box terminals. For example, water in the box can create an electrical leak path, causing the residual differential circuit breaker (DR) disappear. Therefore, make sure the junction box is properly sealed and there are no signs of moisture in the box. Another possible explanation is that the cables at the terminals may have poor connection or no connection at all due to incorrect work during cutting and connection..

Stage 3: Check End Seal

In rare cases, end seal failures may occur, causing a defect. For example, incorrect work may result in moisture or water entering the final seal. When this happens, immediately replace the end seal.

Thermostats

Finally, use a voltmeter to check that the mechanical thermostat's internal relay is turning on and off correctly. Replace it if there is a defect. On the other hand, when inspecting an electronic thermostat, you must take additional safety precautions, because there is voltage applied to the electrical trace thermostat.

You can simulate a low temperature with a resistor or adjust the thermostat set point to turn on the electronic thermostat. Then, check if the contact inside is on with a voltmeter. Be sure to return the setpoint to its original value when you have finished testing.

Finally, It is essential to point out that these steps are just an overview of how to troubleshoot your electrical trace cables.. We recommend following the specifications provided by the manufacturer and observing work safety protocols at all stages of the inspection. If you are not sure how to proceed, contact a professional to carry out the exam.

When considering maintenance and troubleshooting electrical trace systems, Tayga offers a professional and reliable approach to ensuring the continuous and efficient operation of these systems in your industrial facilities.

Na tayga, We offer customized heating solutions that can be tailored to meet the operational and budgetary requirements of any industry. Our experts are available to guide you in selecting the best heating option for your facility..

Contact us today to learn more about our state-of-the-art heating solutions. We are available through do site (click here) or by e-mail contato@taygahs.com or at phone and Whatsapp (21) 9.8819-3687.

We also recommend reading our materials on the heating and insulation systems implemented by Tayga (just click and you will be redirected):