Steam Trace Systems are widely used in many industrial sectors to heat process equipment.. meantime, some industries that value the efficiency of their processes, use a most modern type of steam heating system, for which the heat transfer from the heating branch to the pipeline is significantly increased, enabling temperatures closer to those of steam to be obtained. We call this type of system High Performance Steam Tracing..

Steam Trace systems are known for heating process equipment, improving energy efficiency, heating accuracy and quality of final products. In these systems, steam serves as a heat transfer medium for heating and maintaining temperature, being conveyed through a pipe – call trace of steam -, to process equipment, where is it released, transferring heat to the product or fluid that needs to be heated.

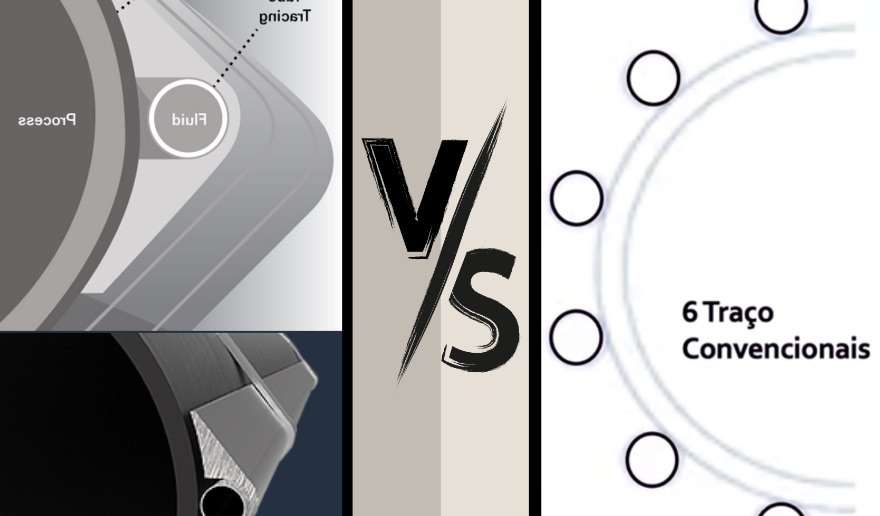

In parallel with the Conventional Steam Trace, the High Performance Steam Trace has been increasingly used., as a more modern solution that can replace the conventional system. So that you understand the main differences between a Conventional Steam Tracing System and a Maximum Performance Steam Tracing System (MHT Maximum Heat Transfer, da Tayga), We put together the comparative table below:

Tayga has already carried out several heating and insulation projects and developed the High Performance Steam Trace solution. To understand how we can help your industry and learn about our projects, Contact us from the site (click here), fur e-mail contato@taygahs.com or at phone and Whatsapp (21) 9.8819-3687.

It will be a pleasure to get to know your industry and help with our customized energy efficiency solutions!

We also recommend reading our materials on the heating and insulation systems implemented by Tayga (just click and you will be redirected):