“Steam tracing is a technology that plays an important role in maintaining the temperature of process media.

There are different types of Steam Trace system designs, like Central Line solutions (Good line), Jacket Tube (Jacket Pipe) and Bare Pipe (Bare Tube Tracing). We will look at these solutions below.“

Central Line System (Good line)

Operation

The centerline steam tracing system uses a central tube that operates at a certain vapor pressure, providing a large heat transfer surface to heat the fluid. This central tube is installed inside the process piping.

Benefits

- Large heat transfer surface area: Larger surface area allows for efficient heat transfer, ideal for processes that require a significant amount of thermal energy.

Disadvantages

- Difficult installation: Proper inner tube support is complex, and penetration of the supply line and condensate into the outer wall of the process tube presents significant challenges.

- Complicated leak detection: Inner tube failures are difficult to detect, which can lead to prolonged maintenance issues.

- Difficult maintenance: Maintaining the inner tube steam system is virtually impossible, resulting in high operational costs and risks.

Jacket Tube System (Jacket Pipe)

Operation

In jacket tube system, the process tube is encapsulated by a surrounding vapor jacket. The jacket completely surrounds the process tube, providing a large heat transfer surface area, ideal for processes that require high energy addition.

Benefits

- Large heat transfer surface area: The jacket allows the release of high energy, essential for intensive processes.

- Greater ease of installation: Compared to central steam dash system, installing the jacket is relatively simpler.

Disadvantages

- High installation cost: Jacket pipe installation is expensive due to the complexity of the system and the materials used.

- Hidden weld points and hard-to-detect failure points: Weld failures can cause contamination in the process or condensate drainage system, creating major operational problems.

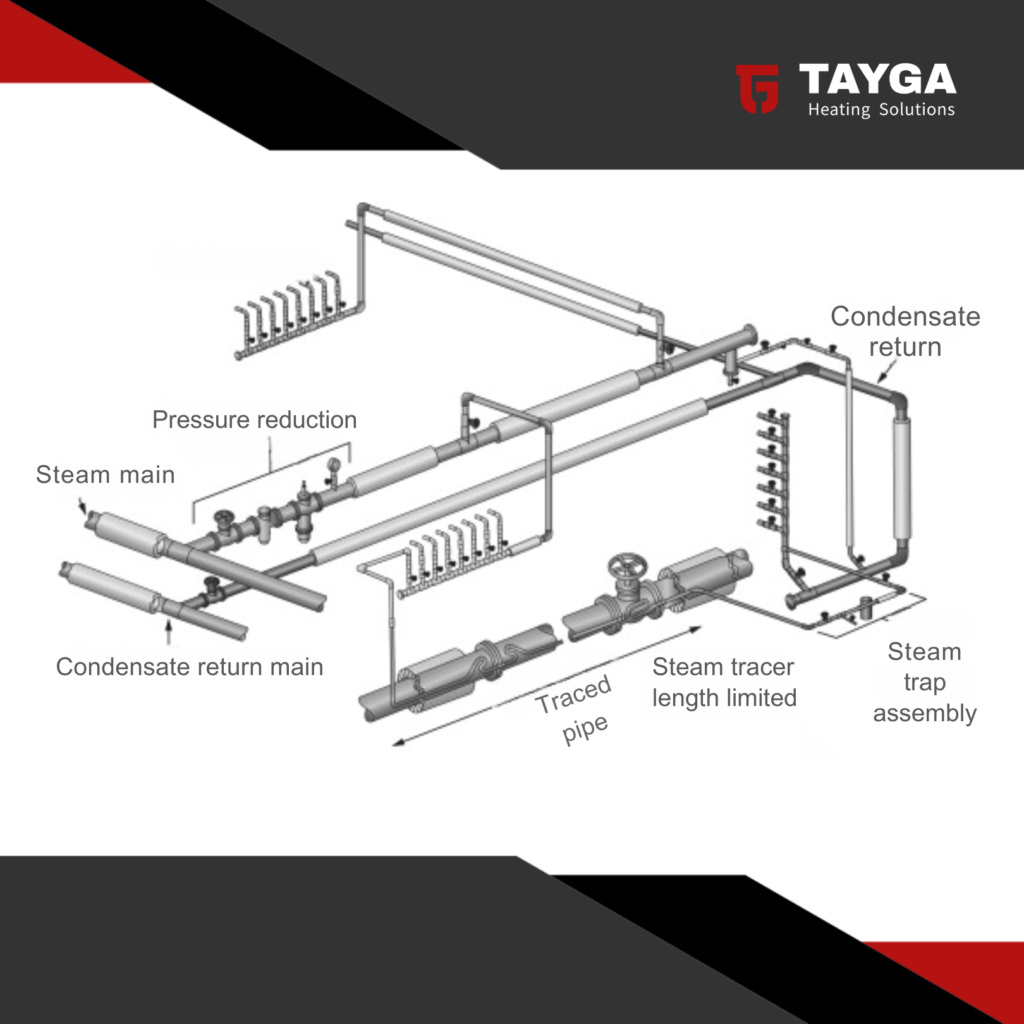

Bare Tube Tracing (Bare Tube Tracing)

Operation

Bare tube tracing involves the external installation of a steam tube along the process piping. This method is widely used due to its ease of installation and maintenance.

Benefits

- Easy to install: External installation is simple and quick, reducing time and associated costs.

- Easy to maintain and modify: Maintenance and changes can be made easily, ensuring operational flexibility.

- Available thermal compounds: Heat transfer compounds can be added to increase system efficiency.

- High reliability: The system is robust and less susceptible to failures.

Disadvantages

- Low heat transfer surface area: Compared to other systems, the surface area available for heat transfer is less, which may limit its application in processes that require high thermal energy.

Comparison between Steam Tracing Systems

Energy Efficiency

- Central Line: High efficiency, but difficult to maintain.

- Jacket Tube: High efficiency with improved ease of installation.

- Tube Discovered: Variable efficiency, but with potential for improvement using thermal compounds.

Reliability and Maintenance

- Central Line: High maintenance complexity and difficult fault detection.

- Jacket Tube: Better maintenance compared to central line, but with risks of hidden flaws.

- Tube Discovered: Easy maintenance and high reliability.

Installation Cost

- Central Line: High cost due to complexity.

- Jacket Tube: High cost, but with justification for intensive processes.

- Tube Discovered: Low cost and easy installation.

Conclusion: Tayga as Steam Dash Supplier

Tayga stands out as a leader in providing steam tracing solutions, offering systems that guarantee efficiency, reliability and innovation. Our High Performance Steam Tracing systems provide superior heat transfer and are designed to meet each customer's specific demands.

Benefits of Choosing Tayga

- Energy efficiency: Our systems are designed to maximize heat transfer with minimal energy loss.

- Reliability: Robust and durable products that reduce the need for frequent maintenance.

- Technical support: Our team offers specialized technical support to ensure correct installation and optimal functioning of systems.

- Customization: We offer customized solutions to meet the specific needs of each client.

Investing in Tayga's steam tracing systems ensures efficient operation, safe and economical for your industrial facilities. To learn more about how Tayga heating and insulation solutions can benefit your business, contact us today.

We are available through do site (click here) or by e-mail contato@taygahs.com or at phone and Whatsapp (21) 9.8819-3687.

We also recommend reading our materials on the heating and insulation systems implemented by Tayga (just click and you will be redirected):