“Electrical Tracing is a crucial technique in many industries, which provides an effective means of heating for pipes, tanks and equipment. However, Proper installation of the electrical trace is essential to ensure its operational efficiency and safety.

In this article, Let's explore Tayga's electrical dash installation process, highlighting the key steps and expertise required to ensure exceptional results.”

Stage 1: Preparation and Initial Inspection

The electrical trace installation process begins with careful site preparation and an initial inspection of the piping.

Na tayga, We carry out a thorough manual cleaning of the pipes to eliminate any dust, dirt or residue that could compromise the installation of the electrical trace.

Besides that, We conduct a detailed inspection to identify any burrs or foreign bodies that may interfere with the installation process.

Stage 2: Fixing the Electrical Trace

With pipes properly cleaned and inspected, we proceed to fix the electrical trace.

For this, We use strong and durable fiberglass tapes that are applied circumferentially around the pipes. These tapes guarantee a firm and secure fixation of the electrical trace, providing uniform heat distribution over the surface of the pipes.

Stage 3: Assembly of Connection Boxes and Temperature Sensors

After installing the electrical trace, It's time to assemble the connection boxes and temperature sensors. These components are essential for monitoring and controlling the heating system, ensuring temperatures are maintained within safe operating limits.

Na tayga, We use high quality metal clamps to secure the connection boxes and temperature sensors to the pipes, ensuring a safe and reliable installation.

Stage 4: Tests and Verifications

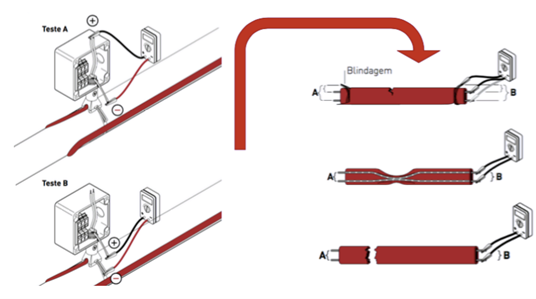

After assembling the components, We carry out a series of tests and checks to ensure the integrity and performance of the Electric Tracing system.

We use a megohmmeter to check the insulation resistance, carrying out rigorous testing to ensure there are no faults or short circuits.

Besides that, We conduct continuity and resistance tests using a multimeter to ensure all connections are working properly.

Stage 5: Completion and Release of the System

Upon successful completion of tests and verifications, we completed the installation of the Electrical Trace and released the system for the application of thermal insulation.

This last step is crucial to ensure that the heat generated by the electrical trace is retained and directed to the pipes., tanks or equipment as needed.

Advantages of Installing Electric Tracing by Tayga

Tayga's electrical trace installation offers a series of advantages for industrial customers. Our team of highly qualified and experienced experts have the knowledge and experience required to ensure each project is completed successfully., from the planning phase to final implementation.

Besides that, Our high-quality products and results-oriented approach ensure operational efficiency, reliability and safety in all applications.

Conclusion

Electrical dash installation is a complex process that requires technical expertise and attention to detail..

Na tayga, We are committed to providing state-of-the-art heating solutions that meet the unique needs of our industrial customers.

With a personalized and results-oriented approach, we guarantee efficiency, reliability and safety in all our Electric Tracing installations.

Na tayga, We offer customized heating solutions that can be tailored to meet the operational and budgetary requirements of any industry. Our experts are available to guide you in selecting the best heating option for your facility..

Contact us today to learn more about our state-of-the-art heating solutions. We are available through do site (click here) or by e-mail contato@taygahs.com or at phone and Whatsapp (21) 9.8819-3687.

We also recommend reading our materials on the heating and insulation systems implemented by Tayga (just click and you will be redirected):