“During the installation of a High Performance Steam Dash System, We use a component of great importance for the perfect functioning of the System: o HTC (Heat Transfer Compound). We will see below what HTC is and how it contributes to the effectiveness of Traço a Vapor.“

Importance of Efficient Heating in Industrial Operations

Several chemical operations depend on some pipe heating system, equipment and tanks. Lack of adequate heating can result in materials freezing, changes in component properties and, ultimately, in the closure of entire industrial facilities, such as processing plants or refineries.

There are several technologies used in heating industrial processes. Among them, the Steam Stroke and the High Performance Steam Stroke.

The Steam Dash

The steam trace is a heating system used in industrial plants to maintain the temperature of pipes, equipment and tanks. It works circulating steam around these elements, preventing the freezing of fluids in cold environments and maintaining the fluidity of processes.

It is widely applied, since the beginning of the last century, in chemical industries, petrochemical and food industries to ensure operational efficiency and equipment integrity.

The High Performance Steam Dash

In recent years, one new version of Traço a Vapor is gaining notoriety: O High Performance Steam Trace. This represents a significant advance compared to the first, used since the beginning of the last century.

High Performance Steam Stroke employs more efficient technologies, ensuring superior heat transfer and more accurate temperature maintenance of industrial systems. This results in a greater energy efficiency, less vapor waste and more effective protection against freezing and solidification of fluids in low temperature environments.

However, It is essential to ensure correct and adequate installation of the High Performance Steam Dash System, especially in critical processes and in environments with vapors containing sulfur compounds. This is essential for ensure the long-term success of these systems and maintain the efficient operation of industrial facilities.

The Crucial Component: HTC (Heat Transfer Compound)

We have already spoken before (click to consult) about the High Performance Steam Dash System installation process. Although, for the correct functioning of this system, there is a crucial component which we will explain below: o HTC (Heat Transfer Compound).

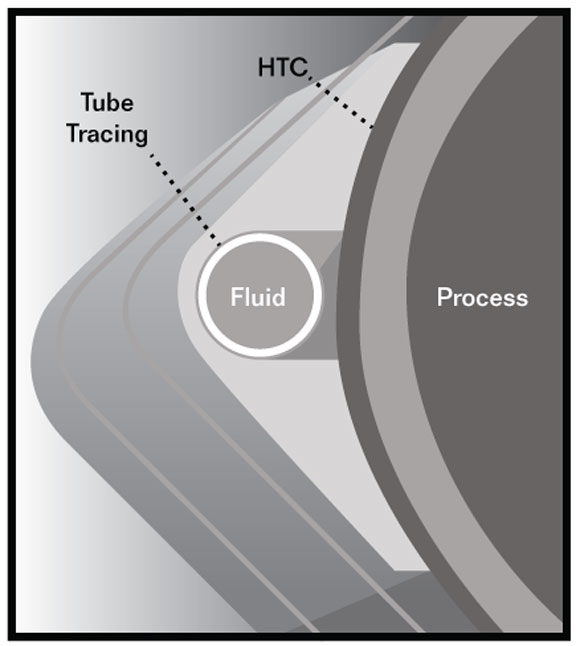

The HTC is one of the most misunderstood and misused components of the High Performance Steam Dash System. He's kind of heat-conducting mass designed to fill small air gaps between the Steam Trace and the object to be heated, understand below.

It heat-conducting mass is considerably more effective at transferring heat than static air, but has relatively low thermal conductivity compared to other components of a Steam Tracing System. Although, with used in very thin layers, HTC helps maximize performance of heating systems.

Technology Behind the High-Performance Steam Tracing System: FTS

To understand how HTC thickness and installation quality affect Steam Trace performance, It is necessary to understand the technology used in the High Performance Steam Tracing System: o Fluid Tracing System (FTS).

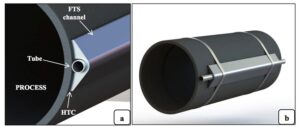

The FTS consists of four separate parts that are assembled during installation.

- traceament tube: contains fluid heating medium;

- Extruded aluminum gutter: to precisely fit the outer diameter of the process vessel;

- HTC: high thermal conductivity mass used to increase heat transfer between two surfaces;

- Stainless Steel Band: used to secure the system to a pipe or container.

These four elements are assembled during installation as follows (figure below):

Extruded aluminum trough precisely fits the outer diameter of the process vessel. The trace tube and HTC are compressed down the chute next to a tube or container with the help of a stainless steel band, that involves all the other elements.

Challenges and Best Practices in Using HTC

Apply Excess HTC between the vapor trace and the wall of the tube or container can have more harmful effects in the long term than decreasing the heating time.

As the system performs thermal cycles, thick layers of HTC dry, weaken and fall, leaving open space between the steam trace and the equipment to be heated.

HTC can also be corroded and displaced by excess moisture, creating unwanted air gaps.

These complications transform the nature of the Trace System from conductive to convective., making it ineffective and unpredictable.

Secrets to an Efficient Steam Dash System

Some secrets to ensuring the performance of the High Performance Steam Stroke are:

- Train and educate installers about the characteristics of HTC, so that its capabilities are well understood and properly implemented in the field;

- Use Steam Trace Systems that are fit perfectly onto the surface of the equipment to be heated, allowing excellent compression, HTC thin layer containment and protection;

- Avoid installing trace elements on weld seams and irregular surfaces of pipes that create gaps, which must be completed with HTC;

Scooter: reference in High Performance Steam Tracing

The High Performance Steam Tracing system used by Tayga offers a performance up to 6 times higher in terms of energy efficiency and heat transfer, ensuring uniform heat distribution throughout pipes and other equipment.

Tayga is a leader in the development of advanced solutions for industrial heating and insulation, standing out for its customer-centric approach, efficient and reliable products, and ability to meet demanding industry demands. Count on our team to design and provide personalized solutions for your needs.

When choosing Tayga heating and insulation solutions, you guarantee the integrity and performance of your processes. To learn more about how Tayga heating and insulation solutions can benefit your business, contact us today.

Contact us today to learn more about our state-of-the-art heating solutions. We are available through do site (click here) or by e-mail contato@taygahs.com or at phone and Whatsapp (21) 9.8819-3687.

We also recommend reading our materials on the heating and insulation systems implemented by Tayga (just click and you will be redirected):