“Steam Trace plays a crucial role in industrial environments, preventing solidification of vital fluids in pipelines and ensuring operational efficiency. One of the essential considerations when designing Steam Tracing systems is to determine the typical circuit length. Let's explore what influences this decision and how to achieve the ideal configuration.”

Factors Affecting Circuit Length

- Heat Loss: The length of the circuit is directly influenced by the rate of heat loss of the fluid in the system. This heat loss is affected by the temperature difference between the fluid and the ambient temperature..

- Environmental conditions: Factors such as ambient temperature, wind speed and thermal insulation play a critical role. In colder climates, with high wind speeds, heat loss can be more significant.

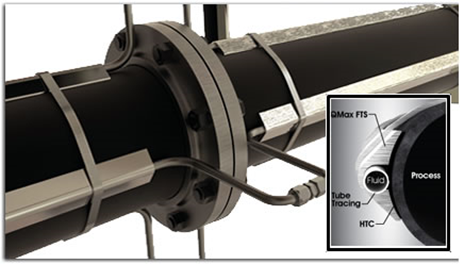

- Tracer Type: The type of tracer, six metal pipe, directly influences the length of the circuit. Heat transfer efficiency will determine specific needs.

- Fluid Properties: The thermal characteristics of the fluid being transported are also crucial. More viscous or dense fluids may require tracing with greater external contact with the piping to prevent solidification.

Steps to Determine Optimal Circuit Length

- Process Assessment: Understanding specific process requirements is critical. This includes the ideal operating temperature and the sensitivity of the fluid to temperature variations.

- Thermal analysis: Performing a system thermal analysis helps identify critical areas that may require different circuit lengths. This is particularly relevant in pipelines exposed to different environmental conditions..

- Selection of the Suitable Tracer: Choosing the right type of tracer based on fluid properties and operating conditions is crucial.

- Consultation with Experts: In so many cases, Consulting with Steam Trace experts can provide valuable insights. Experienced professionals can consider a variety of factors and provide personalized guidance.

Conclusion

Typical circuit length for Steam Trace varies widely based on the specific conditions of each application. Understand the nuances of the process, Fluid properties and environmental conditions are essential to designing an efficient and reliable system.

Choosing Tayga's High Performance Vapor Trace, with its significant benefits, can be the ideal solution to guarantee the effectiveness and reliability of the industrial process.

Na tayga, we are ready to work side by side with you, understanding your needs and offering personalized solutions that boost your business. Contact us today and discover how our solutions can make a difference in your industry.

We are available through do site (click here) or by e-mail contato@taygahs.com or at phone and Whatsapp (21) 9.8819-3687.

It will be a pleasure to get to know your industry and help with our customized energy efficiency solutions!

We also recommend reading our materials on the heating and insulation systems implemented by Tayga (just click and you will be redirected):