“In day 28 April celebrates the World Day for Safety and Health at Work. Safety at work is an important area, who studies ways to maintain the protection of workers in their professional environment. On Scooter, we take this matter seriously. That is why, our professionals are equipped with updated certificates of several Regulatory Norms (NRs) inherent to operations in the industrial environment.

Want to know more about certificates? Check below the list of NRs adopted by our company.”

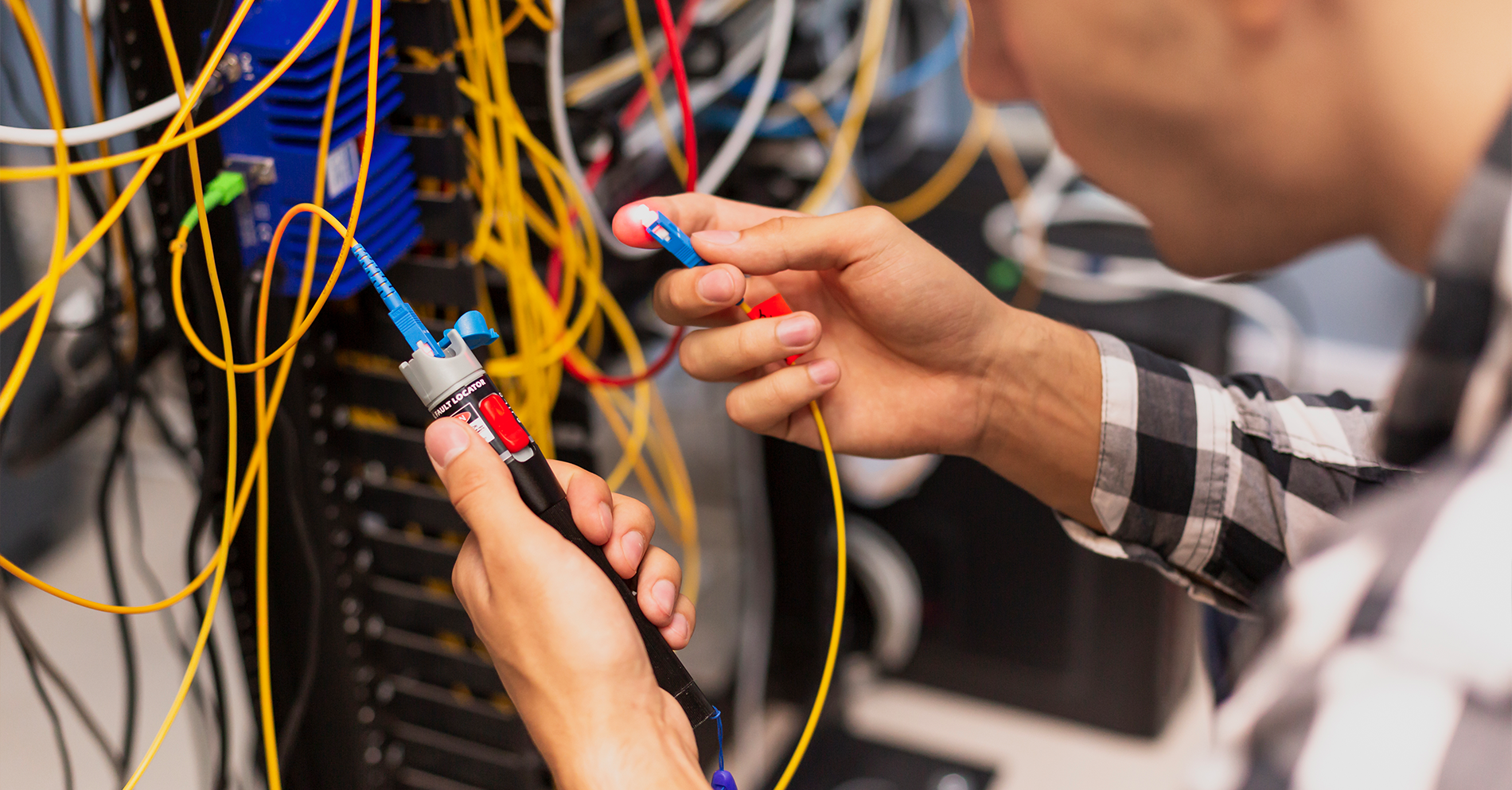

NR10 | Electricians

This NR regulates services that involve electricity. These services can be linked to the generation, streaming, distribution and consumption, maintenance of facilities or any other work carried out in the vicinity.

This NR regulates services that involve electricity. These services can be linked to the generation, streaming, distribution and consumption, maintenance of facilities or any other work carried out in the vicinity.

Besides that, NR10 also presents rules on safety signs, blocks and delimitations of risk areas.

One of its requirements is that every professional connected to the electrical activity carry out a 40h training on the subject. This course covers the characteristics of the work, scratchs, control measures and all the procedures that must be taken in case of accidents.

NR35 | Works at Height

The Regulatory Standard 35 delimits the requirements minimum protection for working at heights, involving planning, organization and execution. Ie, it guarantees the safety and health of workers directly or indirectly involved in work at height.

The Regulatory Standard 35 delimits the requirements minimum protection for working at heights, involving planning, organization and execution. Ie, it guarantees the safety and health of workers directly or indirectly involved in work at height.

Falls due to lack of safety at work at height are among the main causes of death for construction workers, for example. A NR 35 aims to decrease the number of such accidents.

It is important to point out that working at heights can only be carried out by employees who are, at the same time, trained and authorized.

NR33 | Confined Environments

Regulates all work carried out in confined environments. NR33 provides instructions on how to proceed in these activities, the necessary equipment, rescuer and supervisor, lifting equipment, among other information.

Regulates all work carried out in confined environments. NR33 provides instructions on how to proceed in these activities, the necessary equipment, rescuer and supervisor, lifting equipment, among other information.

There are several details that must be observed to perform the activity in a safely confined environment.

THE training is carried out in a confined space lasting two days and prepares the professional to perform the activities, analyze risks and deal with adversities or accidents.

According to NR33 a confined space is any area or place not designed for human occupation on a continuous basis, which has limited means of entry and exit and insufficient ventilation to remove contaminants, as well as where there may be oxygen deficiency or enrichment.

We can quote as examples the pipes, the tanks, the water pipelines, storage silos, boilers, ovens, mixers, reactors, dryers, dyeing containers, between others.

NR05 | internal commission of accident prevention

Responsible for creating parameters for the operation the internal accident prevention commission (CIPA). In any company that has more than 100 employees, the creation of an Internal Accident Prevention Commission is mandatory, or simply CIPA.

Responsible for creating parameters for the operation the internal accident prevention commission (CIPA). In any company that has more than 100 employees, the creation of an Internal Accident Prevention Commission is mandatory, or simply CIPA.

NR's role-05, through CIPA, is to promote awareness among employers and employees so that they are adopted and obeyed safety standards in the workplace such as personal protective equipment and other protective measures that protect the employee.

CIPA acts through lectures, inspections and encouraging the use of personal protective equipment (EPI) by employees. This is because CIPA is also responsible for creating mechanisms that prevent the appearance of illnesses arising from work among employees..

It is important to emphasize that in any institution where there are more than 100 people working it is necessary to have a CIPA formed.

NR12 | Safety at Work in Machinery and Equipment

Aims ensure that machines and equipment are safe for the worker's use and have collective and individual protection measures, in addition to administrative measures.

Aims ensure that machines and equipment are safe for the worker's use and have collective and individual protection measures, in addition to administrative measures.

A NR 12 requires complete information about the entire life cycle of machinery and equipment, including transportation, installation, use, maintenance and even its disposal at the end of its useful life.

Among the objectives of the standard, they are:

– Worker safety;

– Improvements in working conditions in presses and the like, injection molding machines, general purpose machinery and equipment, and other attachments;

– Intrinsically safe machines and equipment.

NR18 | Occupational Safety and Health in the Construction Industry

Determine guidelines on working environment conditions in industry and construction. The standard directs employers and employees regarding best administrative practices, planning and organization.

Determine guidelines on working environment conditions in industry and construction. The standard directs employers and employees regarding best administrative practices, planning and organization.

In this standard, several guidelines on outpatients are determined, sanitary facilities, kitchen, leisure areas and other indications referring to areas of living in the work environment. Besides that, some good practices on the stock of materials are listed, PPE and EPCs, about demolition, electrical installations, carpentry and concrete and metal structures.

NR34 | Working Conditions and Environment in the Shipbuilding and Repair Industry

As it is an area of activity with a high degree of risk, and with great chances of an accident occurring, a NR 34 was developed to deal directly with the shipbuilding industry.

As it is an area of activity with a high degree of risk, and with great chances of an accident occurring, a NR 34 was developed to deal directly with the shipbuilding industry.

All workers in the construction industry, naval repair and disassembly should receive training for training in the activities to be developed in the work routine.

Workers should be qualified, qualified or trained through admission and periodic training for the development of their activities.

NR37 | Safety and Health in Oil Rigs

This standard was developed with the aim of reduce the number of accidents and occupational diseases, as contribute to preserving the marine environment and the integrity of the different platforms involved in the entire production process of the oil industry.

This standard was developed with the aim of reduce the number of accidents and occupational diseases, as contribute to preserving the marine environment and the integrity of the different platforms involved in the entire production process of the oil industry.

NR37 governs all activities that occur in the Offshore. It is separated by topics, that have their own requirements. Among some of them, we can identify the need for training for on-board staff or service provider.

The topics covered by this standard are:

– Working conditions and environment on oil platforms;

– Identification and control of existing risks on oil platforms;

– Specific work and safety procedures on board;

– Protective equipment and emergency procedures.

In addition to these certificates, our professionals are instructed with: Basic Course in Platform Security (CBSP), TRAINING HUET (Helicopter Underwater Escape Training | Submerged Aircraft Escape Training) e Machine and Crane Operators Certificate.

Our team has various tools and equipment suitable for performance in heating and industrial insulation projects. The services developed by Scooter excel for high quality, safety and performance.

To understand how Tayga can help your industry and learn about our projects, contact from the site (click here), fur e-mail daniel@taygahs.com or at phone and Whatsapp (21) 9.8819-3687

It will be a pleasure to get to know your business and help with our customized energy efficiency solutions!

For more information on certificates, courses, attestations and equipment from our team, access:

We also recommend reading our materials on the heating and insulation systems implemented by Tayga (just click and you will be redirected):