The steam heating system is essential for many industries, However, the presence of leaks and failures in this system can cause significant problems, such as corrosion under insulation. Corrosion is a phenomenon that can cause significant damage to industrial facilities, affecting security, the efficiency and useful life of equipment. Let's see below how it happens and what can be done to avoid this type of situation..

The problem

Corrosion under insulation is especially problematic, as it can occur without being detected, causing harm before it can be identified and corrected. A The main cause of corrosion under insulation is the presence of water, which may be provided by leaks in the vapor trace.

That is one relatively common problem with conventional steam traces, that are made, mostly, coppermade, a material highly susceptible to corrosion, especially when exposed to water. The copper, being a highly conductive material, facilitates the passage of electricity, which increases corrosion. All of this can result in leaks and system failures., causing significant damage to industrial facilities, affecting security, the efficiency and useful life of equipment.

THE The use of copper heating tubes also leads to greater fouling of purge stations, which in turn generates a greater number of replacements and maintenance of purging stations.

How to avoid?

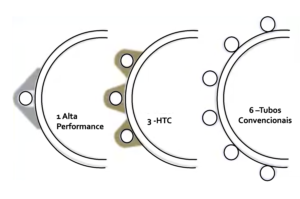

The solution to the problem of corrosion in steam trace systems is the implementation of high performance traces, made of stainless steel. This material is highly resistant to corrosion and water, which makes it ideal for use in harsh environments. Added to this, stainless steel has a much longer lifespan than copper, which means that needs to be replaced less frequently. Besides that, the use of stainless steel prevents fouling in purging stations, ensuring a greater efficiency and security in the system.

Another advantage of stainless steel is that it does not mar or clog the lines, thus avoiding the need for frequent interventions, which results in fewer production stops and less maintenance costs.

In summary, if you are suffering from a lot of leaks and failures in your steam heating system, Implementing high-performance steam traces can be the solution to protect your industrial facilities against corrosion under insulation and ensure safety, efficiency and useful life of equipment.

A Tayga, leading company in the supply of high performance vapor traces, uses exclusive MHT technology. With our high-quality products and customized solutions, We can help protect your industrial facilities against corrosion under insulation, ensuring security, efficiency and useful life of equipment.

No longer suffer from leaks and failures in your steam heating system, Trust Tayga to provide the high-performance steam tracing solutions your business needs. Contact us from the site (click here), fur e-mail contato@taygahs.com or at phone and Whatsapp (21) 9.8819-3687 to find out how we can help your company.

We also recommend reading our materials on the heating and insulation systems implemented by Tayga (just click and you will be redirected):