“The system of electric trace stand out-know how one of the most reliable solutions for maintaining liquids flowing into the tubes at the desired temperatures. Learn more about this system, that has been used by industries in controlling process temperature.“

A liquid has a unique property that allows it to thicken and become solid at lower temperatures. However, for process industries dealing with liquids, this phase change is a problem.

During cold weather conditions, liquids can freeze, blocking or restricting the flow within the tubes. In extreme cases, the increase in pressure inside the tubes can lead to cracks or even the tubes can explode, causing serious injury to people working near the processing system.

It is fundamental, So, have one functioning system that keeps liquids flowing inside the tubes at the desired temperatures.

The system of electric trace basically does this and is one of the most reliable ways to ccontrol temperatures in the process tubes.

The Electric Trace system

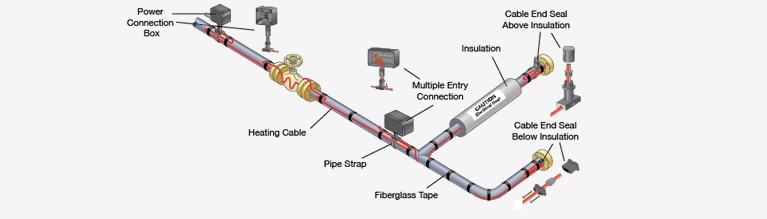

It is a set of paths aligned along tubes or vessels. These paths are made up of a resistive element that heats up when electricity passes through it.

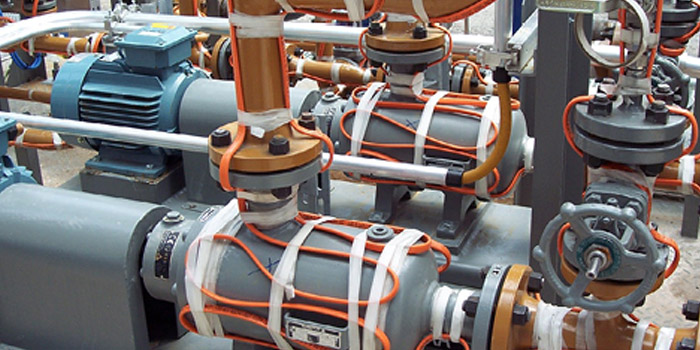

THE electric tracing system is able to maintain process temperature in pipelines, glasses, silos, valves, flanges, bombs, filters, instruments, supports, tremonhas, gravimetric feeders and other process equipment within a specific temperature range, during exposure to ambient conditions or heating such equipment, in special cases.

How to choose the perfect electrical tracing system?

It is important to create a custom electric dash system for a specific process application, selecting the right type of cables for the strokes. Besides that, it is possible to control the amount of heat generation through these cables, varying the power of the cable to meet specific processing fluid requirements.

For this, it is essential to choose one partner company that makes the design of the heating system by electric trace according to your demand. The company must be able to ensure that the electrical trace system is able to maintain the process temperature, of the fluid or product to be transported and that this system presents the necessary mechanical and thermal resistance, so that, under normal conditions of use and operation, your performance is reliable and does not represent a source of risk or danger for users, facilities or environment.

To know the Tayga's electrical tracing solution and know more about all the heating and insulation projects that we have already carried out, contact with us from the site (click here) or send an email to contato@taygahs.com.

It will be a pleasure to get to know your industry and help with our customized energy efficiency solutions!